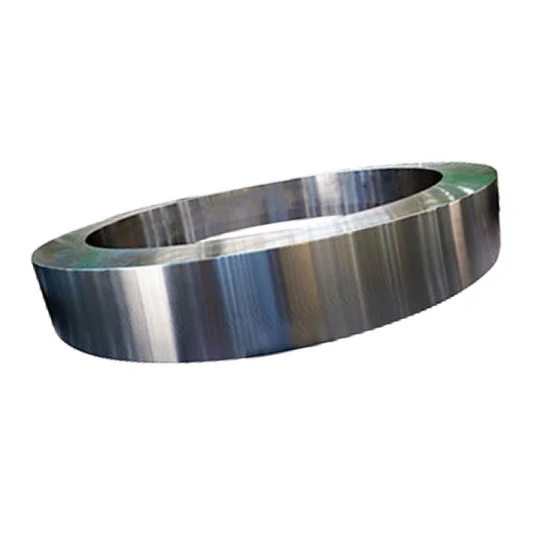

OEM Forge Part Hot Forging Metal Forged CNC Aluminum Forgings for Motorcycle Parts

Basic Info

| Model NO. | FG-032 |

| Surface Treatment | Oxidation |

| Forging Tolerance | +/-0.5mm |

| Standard | GB |

| Certification | ISO 9001:2000 |

| Transport Package | Package |

| Specification | 415mm |

| Trademark | OEM |

| Origin | China |

| HS Code | 7616909090 |

| Production Capacity | 600000 / Year |

Product Description

Factory Customized Precision Aluminum Alloy Forging Die Casting To Make Radiators

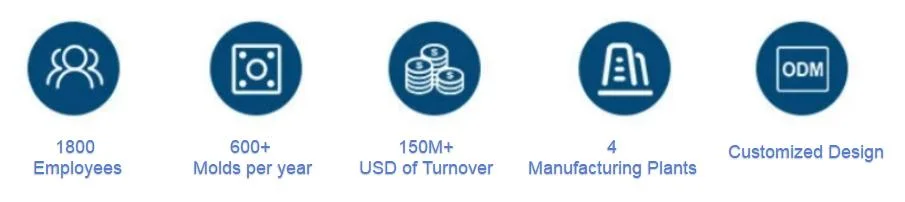

- Focus on the customization of high-end aluminum alloy die castings for 20 years.

- We are a one-stop manufacturer integrating mold design, product die-casting, and surface treatment.

- One-stop production, fast delivery, and perfect quality control, the qualified rate of quality reaches 98.6%.

- The quality is controllable, and the on-time delivery rate is 99.8%.

- More than 10,000+ die-casting mold customization experience, support customized processing with drawings and samples.

| Services | OEM/Customized |

| Product | Aluminum Forgings / Die-casting parts / CNC Precision Machining Products |

| Material Grade | Aluminum alloy 2000, 4000, 5000, 6000 & 7000 series, T3-T8 |

| Surface Treatment | Plating, Powder Coating, Polishing, Painting, Matte, Deburring, etc |

| Deep Processing | Cutting / Drilling / Forging / Die Casting / CNC Machining and so on. |

| Model Number | According to your 2D /3D drawings / samples / customization |

| Size |

|

| Features |

|

| Drawing Format | 3D (stp, igs) |

| Quality Control | 100% Inspection |

Q1. Are you a factory or trade company?

We are a factory with manufacturing of Aluminum materials and deep processing over 20 years.

Q2. What kind of production services do you provide?

Mold opening, Die-casting, Forging, Aluminum extrusion, Surface treatment, CNC precision machining products and so on.

Q3. How long should we take for a quotation?

After receiving the 2D/3D drawings (technical specification) or samples, we will quote you within 2 working days.

Q4. What materials can your company do?

Our company can make aluminum alloy materials in 2000, 4000, 5000, 6000 & 7000 series, T3-T8, and related customized aluminum finished products manufacturing and processing.

Q5. What is your quotation element?

Product structure, material, size, craftsmanship, weight, quality, order and other information

Q6. How can we guarantee quality?

Always an approved pre-production sample before mass production;

Always final Inspection before shipment.

Please feel free to contact with us for a further discussion!